and animals

of the Environment

to assembly of sections

-

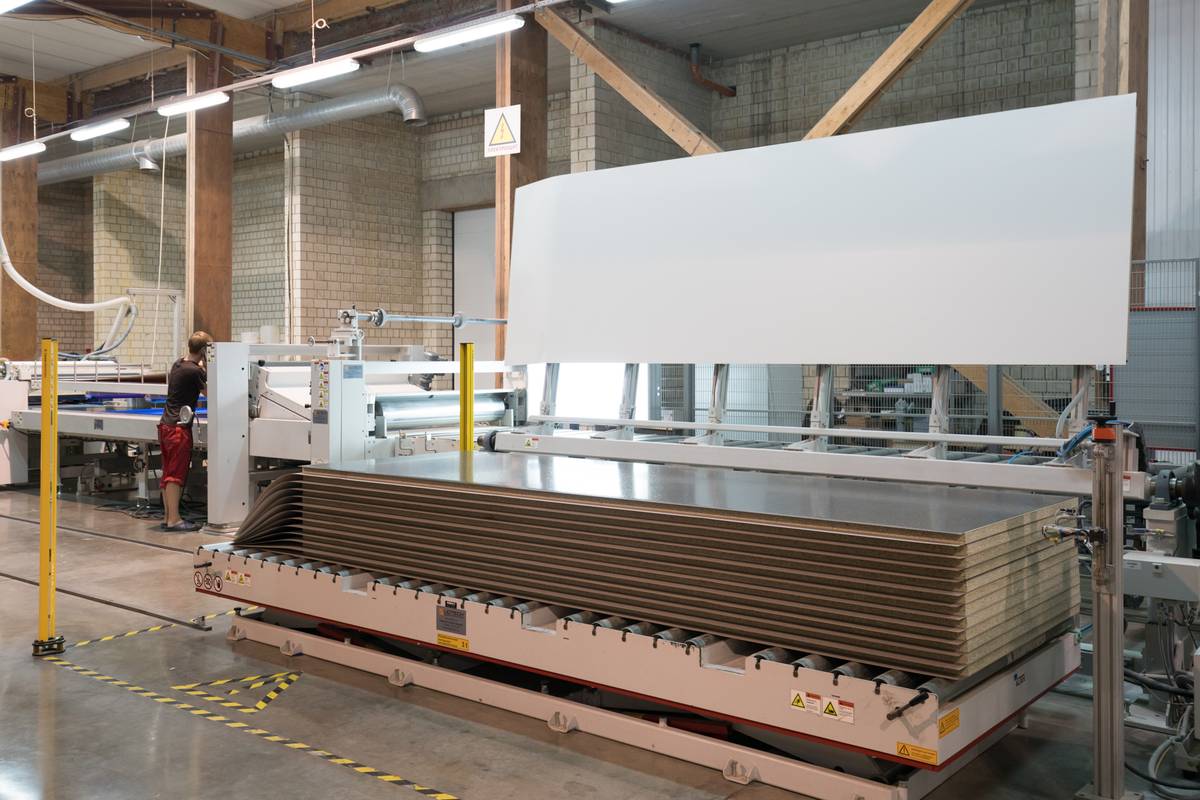

Frame shopWhat is at the heart of the kitchen?Frame shopEvery day 12,000 frame parts are manufactured at the «Maria» factory

![]() Cutting error is minimal

Cutting error is minimal![]() Assembly holes are made quickly and accurately

Assembly holes are made quickly and accurately![]() Chipboard by Standard or laminated chipboard with increased moisture resistance by AquaStop Egger

Chipboard by Standard or laminated chipboard with increased moisture resistance by AquaStop EggerThe frame is the skeleton of the kitchen — it’s backbone . The service life of the furniture directly depends on how strong, reliable and durable it is. Frames for «Maria» kitchens are made of chipboard from the world’s largest manufacturers from Austria such as Egger and Kronospan.

A chipboard sheet is sawn into pieces of the required dimensions on a Holmza machine (Germany). The equipment is controlled by a computer, so cutting error is minimal. The material is placed on an air cushion, which protects it from scratches.

We use WEKE machine (Germany), which also has program control, to make quick and accurate holes for assembling the frame section.

Chipboard, which "Maria" kitchens are made from, complies with E1 environmental safety class: it is odorless, does not cause allergies and is safe for children’s health.

-

Facade shopHow does a design idea come to life?Facade shopIn the Facade shop kitchen facades are made from MDF or chipboard for classic, neoclassical and modern kitchens

![]() An edge of 5 colors is loaded into a laser machine (Germany)

An edge of 5 colors is loaded into a laser machine (Germany)![]() Double-sided edge by Rehau (Germany) gives a variety of options

Double-sided edge by Rehau (Germany) gives a variety of options![]() The tape is not glued to the facade, but soldered with a laser

The tape is not glued to the facade, but soldered with a laser![]() Milling is done by Homag Vantage 33 (Germany))

Milling is done by Homag Vantage 33 (Germany))![]() Machine by Burkle (Germany) for facing MDF facades

Machine by Burkle (Germany) for facing MDF facades![]() Facades covered with film are ready to be sent to the Assembly shop

Facades covered with film are ready to be sent to the Assembly shop![]() SwissQprint UV printer for photo printing (Switzerland)

SwissQprint UV printer for photo printing (Switzerland)![]() Photo printing: a clear pattern on any surface

Photo printing: a clear pattern on any surfaceIf the frame is the skeleton of the kitchen, the facade is its face. It should not only be attractive, but also emphasizes the individuality of its owners. "Maria" provides clients with unlimited opportunities for creative self-fulfilment. In the facade shop, kitchen facades are made of MDF or chipboard. They can be flat or radius, with milling of any level or glass inserts, covered with matte or glossy film (more than 200 colors in the palette) or with photo printing (more than 250 unique images in the database).

Maria was the first in Russia to master the technology of laser edge processing: the tape is not glued to the facade, but soldered with a laser, ensuring the tightest fit possible. A perfectly flat surface without visible seams will last long as it is moisture and steam resistant. An edge of five colors is loaded into the ProfiLine KAL 320 laser machine (Germany). Its productivity is 800 parts per day. Double-sided edge by Rehau (Germany) is available in different colors and decorative solutions.

Milling MDF facades is done by the Homag Vantage 33 machine (Germany). Karim Rashid’s signature wave is cut out on the Karma model. It will be made of colored glass and illuminated with the color of the kitchen. Burkle machine (Germany) is used аor lining MDF facades with thermoplastic. Its productivity is 650 items per day.

Another option for decorating a facade is photo printing. The image is applied by a large-format UV flatbed printer SwissQprint (Switzerland). "Maria"’s database contains more than 250 exclusive prints. Photo printing technology allows you to apply a high-definition pattern to any surface including glass wall panels.

-

Facade finishing shopTradition combines technologyFacade finishing shopReady-made facades and dining groups from Italy are decorated here.

![]() Robot Fanuc (Japan) applies paint, imitating moving hand

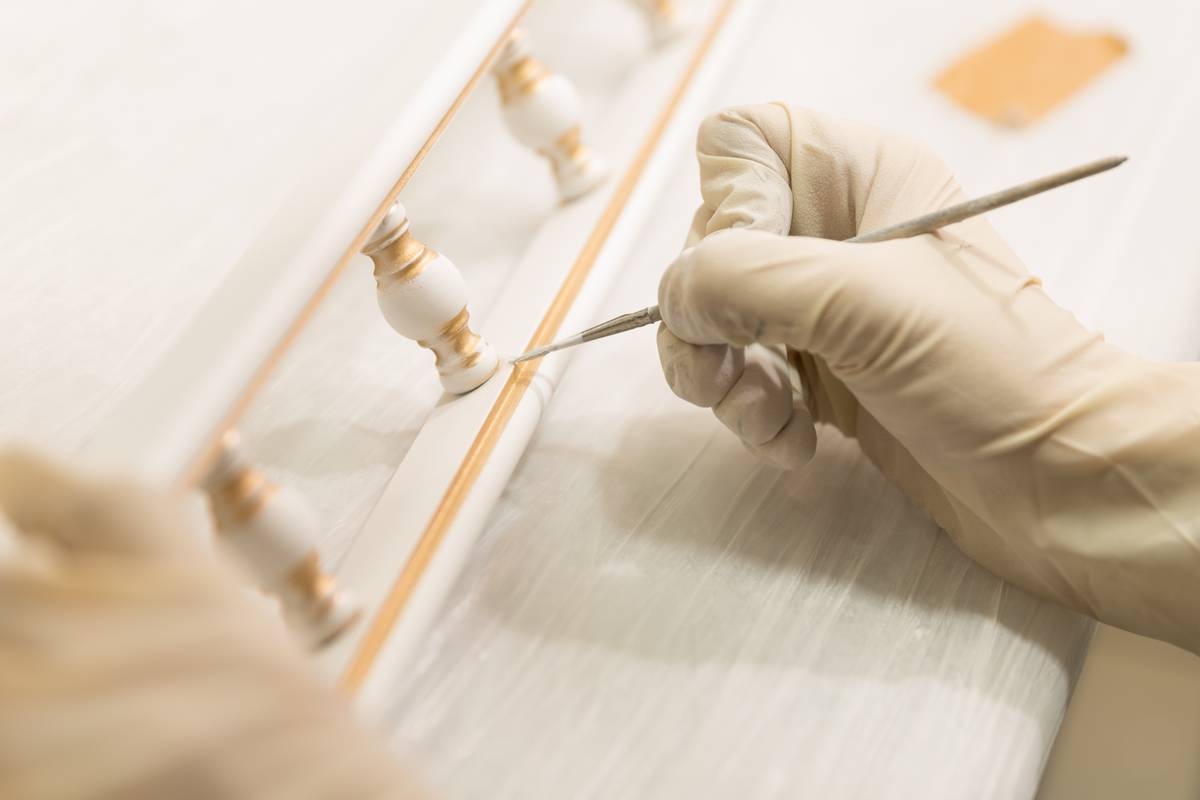

Robot Fanuc (Japan) applies paint, imitating moving hand![]() Artists apply patina by hand

Artists apply patina by hand![]() Wooden elements are prepared for painting by polishing by hand

Wooden elements are prepared for painting by polishing by hand![]() Facades covered with film are ready to be sent to the assembly shop

Facades covered with film are ready to be sent to the assembly shop![]() Finishing polish with a Festool machine (Italy)The future is already here: robots and people create beauty together at the factory. Solid wood facades, as well as all wooden elements and dining groups, are brought from Italy, and at the factory in Saratov they are polished, primed and decorated with paint, varnish or patina. MDF facades go through the same production stages. In order to get the same tone on all parts of one kitchen, the paint is applied by a robot. Even "Maria"'s Italian partners, who come here on excursions, admire its “skill”. Then the kitchen parts are hand-painted by artists. They are trained at the factory. They study for six months before they are entrusted with painting an entire kitchen.

Finishing polish with a Festool machine (Italy)The future is already here: robots and people create beauty together at the factory. Solid wood facades, as well as all wooden elements and dining groups, are brought from Italy, and at the factory in Saratov they are polished, primed and decorated with paint, varnish or patina. MDF facades go through the same production stages. In order to get the same tone on all parts of one kitchen, the paint is applied by a robot. Even "Maria"'s Italian partners, who come here on excursions, admire its “skill”. Then the kitchen parts are hand-painted by artists. They are trained at the factory. They study for six months before they are entrusted with painting an entire kitchen. -

Countertop shopIndustrial artCountertop shop"Sculptors" produce more than 1,500 artificial stone countertops every month. More than 80% of the work is done by hand.

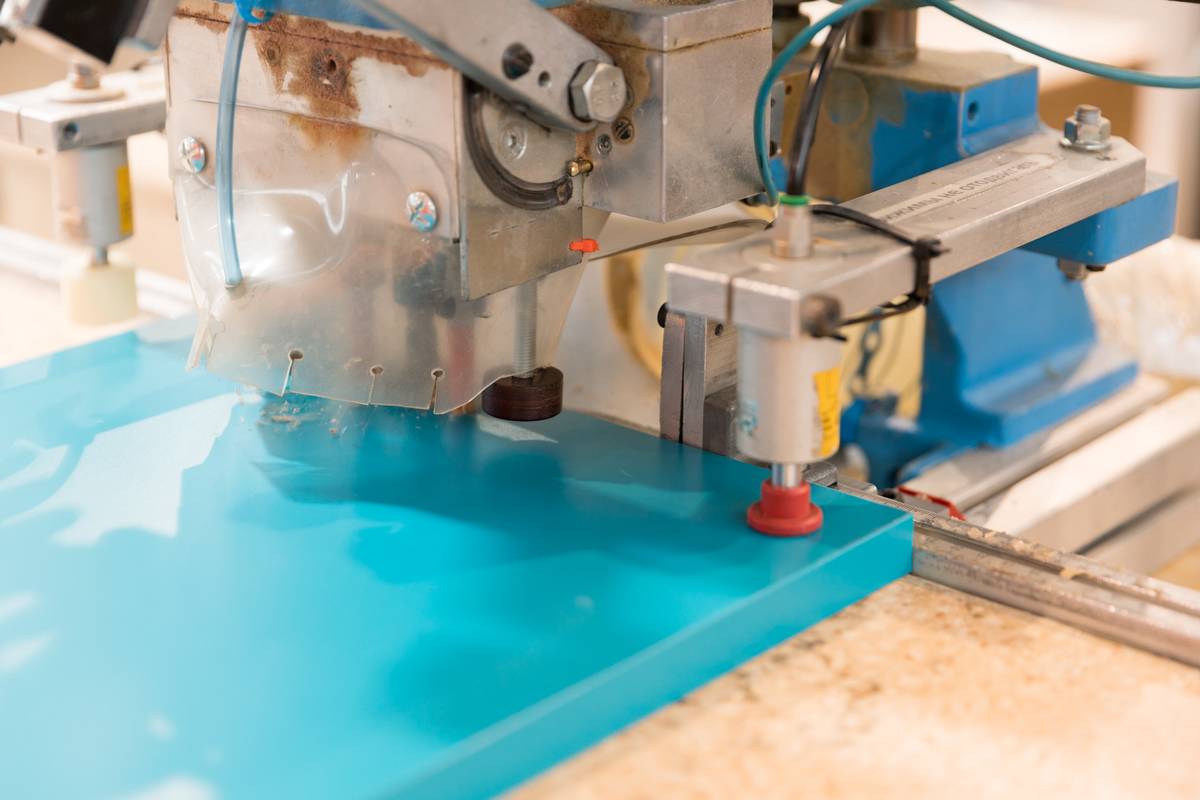

![]() The 12 mm thick stone is a guarantee of strength and durability.

The 12 mm thick stone is a guarantee of strength and durability.![]() After cutting the stone slab, all the elements are glued into a single structure.

After cutting the stone slab, all the elements are glued into a single structure.![]() The final polishing of the stone is done by hand.

The final polishing of the stone is done by hand.![]() Chipboard countertops are veneered with plastic on a Burkle machine (Italy).

Chipboard countertops are veneered with plastic on a Burkle machine (Italy).![]() Personal responsibility for quality of each product"Maria" produces tabletops of two types: from chipboard covered with plastic and from artificial stone. At the chipboard factory, countertops are cut to size, lined with plastic, the ends are processed according to Euro-sawing technology - without visible seams and joints. Wall panels are made from the same material. Artificial stone is used to make not only countertops and back splashes, but also sinks. The sink is integrated to the countertop in such a way that a single design is obtained - without gaps, beautiful and durable. In the factory those people who work with 20 kg stone slabs we call "sculptors". Due to the company's extensive experience with artificial stone the legendary designer Karim Rashid got interested and involved into working with us. He designed for us the Volna concept completely from this artificial stone.

Personal responsibility for quality of each product"Maria" produces tabletops of two types: from chipboard covered with plastic and from artificial stone. At the chipboard factory, countertops are cut to size, lined with plastic, the ends are processed according to Euro-sawing technology - without visible seams and joints. Wall panels are made from the same material. Artificial stone is used to make not only countertops and back splashes, but also sinks. The sink is integrated to the countertop in such a way that a single design is obtained - without gaps, beautiful and durable. In the factory those people who work with 20 kg stone slabs we call "sculptors". Due to the company's extensive experience with artificial stone the legendary designer Karim Rashid got interested and involved into working with us. He designed for us the Volna concept completely from this artificial stone. -

Assembly shopAll about quality controlAssembly shopThere are 13 assembly lines that make sections for 130 kitchens per day.

![]() Drilling holes for the hinges are made on the machine

Drilling holes for the hinges are made on the machine![]() Hettich hinges guarantee 200,000 cycles of trouble-free and silent operation

Hettich hinges guarantee 200,000 cycles of trouble-free and silent operation![]() Each assembled section is photographed

Each assembled section is photographed![]() Each section is checked by a responsible specialist

Each section is checked by a responsible specialist![]() The assembled section is placed in a special moisture-resistant protective packaging.

The assembled section is placed in a special moisture-resistant protective packaging.A chipboard sheet is sawn into pieces of the required dimensions using a Holmza machine (Germany). The equipment is controlled by a computer, so cutting error is minimal. The material is placed on an air cushion, which protects it from scratches.

The program-controlled WEKE machine (Germany) makes holes for assembling the frame section quickly and accurately.

Chipboard, which "Maria" kitchens are made from, complies with E1 environmental safety class: it is odorless, does not cause allergies, and is safe for children's health.